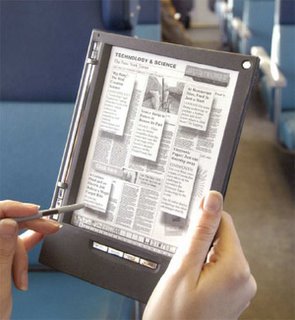

iRex introduces the Iliad

The ER 0100, from iRex Technologies, is a portable electronic device specifically for

reading applications. Its stable, high-brightness display

makes for excellent readability both indoors AND outdoors.

The 8.1-inch (diagonal) monochrome Electronic Paper

display contains 1024 x 768 pixels and supports 16 levels of

grey (160 dpi).

There is a choice of five standard connectivity options for

transferring data to the Electronic reader. The product can

work with a USB stick, Compact Flash and SD memory card

using slots on the top of the device.

Connection to the Internet is possible via integrated WiFi or

Ethernet cable.

Connection to PC/laptop: via USB-cable or integrated WiFi.

The ER 0100 is a very low power mobile device, specifically

designed for reading applications. The operating time of the

rechargeable battery is more than a week without

recharging, based on an average use of three hours reading

a day.

The content can be stored in four different archives (e.g. My

newspapers, My books). These archives can be quickly

accessed using the archive buttons of the device. Advanced

search functions are available to locate the required content

quickly.

The touch screen facility and stylus makes text input (writing

comments on text and scribbling) and easy navigation

possible as part of a very natural user interface.

CONTENT FORMATS SUPPORTED

· PDF

· XHTML

· TXT

· MP3

· Other formats will be supported in the near future

INTERFACES

· USB type A connector for USB memory stick.

· CF type II slot for memory extension or other

applications.

· SD/MMC slot for SD/MMC memory cards.

· 3.5mm stereo audio jack for headset.

· WIFI 802.11g wireless LAN.

· 10/100MB wired LAN.

SYSTEM SPECIFICATION

· 400MHz INTEL X-Scale Processor.

· 64MB Ram

· 224MB free* internal FLASH memory for storing

content (sufficient for 1 month of newspapers, 30

books and many other documents).

· Touch sensor input using stylus.

· Rechargeable battery.

· Cradle and travel charger available.

· Dimensions (wxhxd): 155x217x16 mm. (A5)

· Screen dimensions (wxh): 122x163 mm.

· Weight: 390 grams.

· Operating temperature is 0°C to 50°C.

· Storage temperature is –20°C to 70°C.

(* depends on the amount of installed fonts)