Flexible Electronic Paper

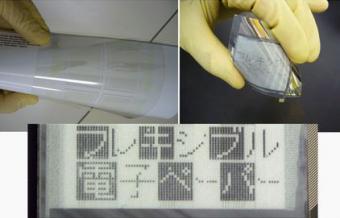

Upper Left: Flexible TFT using Amorphous Oxide Semiconductor Upper Right: Prototype of Flexible Electronic Paper Display Bottom: Close-up of Prototype using Amorphous Oxide Semiconductor TFT (on glass substrate)

Upper Left: Flexible TFT using Amorphous Oxide Semiconductor Upper Right: Prototype of Flexible Electronic Paper Display Bottom: Close-up of Prototype using Amorphous Oxide Semiconductor TFT (on glass substrate)Toppan Printing Co., Ltd. has developed an amorphous oxide semiconductor thin film transistor (TFT) array and succeeded in driving an electrophoretic E Ink front panel laminate to fabricate a prototype flexible electronic paper display.

Today, TFT arrays for conventional Liquid Crystal Displays use amorphous silicon as the semiconductor and are fabricated on glass using a high temperature process.

Toppan has taken note of amorphous oxide semiconductor TFT developed by Professor Hosono of Tokyo Institute of Technology, because of its processability under room temperature and electrical properties that exceed those of amorphous silicon TFT.

Toppan processed these TFTs on a plastic substrate under room temperature and fabricated a flexible electronic paper display by combining it with an electrophoretic E Ink front plane laminate. This is the first time an E Ink electronic paper display has been driven by an oxide semiconductor TFT array.

This plastic substrate, amorphous oxide semiconductor TFT array is thinner, lighter and more robust than glass substrate TFTs and is flexible. Such mechanical properties bring next generation flexible displays closer to reality.

Toppan plans to develop flexible TFTs with goals to commercialize thin, lightweight and flexible displays such as electronic paper, starting with a practical prototype display in fiscal 2008. In parallel, we aim to introduce printing methods into the fabrication process of flexible TFTs for simplification and cost reduction.

Lightweight and flexible displays are considered a promising next generation product. Especially, with the recent developments in the field of electronic paper, led by electrophoretic displays, there is a heightened need to commercialize lightweight and robust flexible TFTs on plastic substrates.

Conventional flat panel displays, like LCDs are driven by TFTs on glass, processed at high temperature (mainly amorphous silicon TFT, fabricated at over 250 degrees centigrade). On the other hand, such a glass-based TFT array has many disadvantages for electronic paper because it is heavy, fragile and rigid (not flexible).

For this reason, many researchers are developing TFTs using plastic substrates, and because high temperature processes are not possible with plastic substrates, there is a lot of research & development for low or room temperature fabrication processes.

Toppan has been conducting research & development for lightweight and flexible TFTs, and one of our significant achievements was "All-Printed Organic Transistors," announced in November, 2003. This research showed that it was technically possible to fabricate a TFT array using organic semiconductor material and with printing processes only. Many researchers worldwide are working on organic TFT, but most of the printable organic semiconductor materials face technical challenges, including electrical properties of low mobility, small on/off ratio and short lifetime issue etc.

Then in the fall of 2004, researchers led by Professor Hosono of Tokyo Institute of Technology reported flexible TFTs using amorphous oxide semiconductor (a-InGaZnO) materials (Nomura et al, Nature 432, 488 (2004)). Toppan took note of this new approach and launched a research and development program using this amorphous oxide semiconductor material. This oxide semiconductor material is room temperature processable and has better electrical properties compared to conventional amorphous silicon semiconductors. It is also possible to apply printing processes for the TFT electrodes using printable metal pastes.

Via Physorg.com / Source: Toppan

0 Comments:

Post a Comment

<< Home